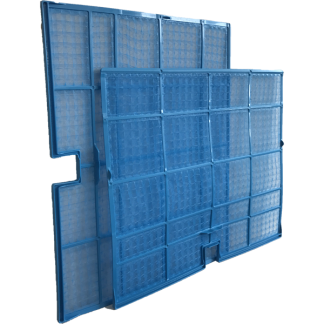

Activated Carbon Panel Filter for Kitchen Odour Removal

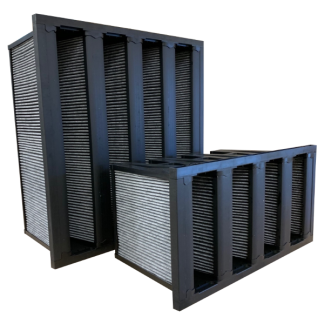

An Activated Carbon Panel Filter is used in Kitchen Extracts to remove odours from the air before discharging to atmosphere. A metal cased carbon discarbs hold multiple bonded panels in a “block” which can then be easily installed into the duct. Carbon panels are available in standard and non standard sizes for suitable installations.

01277 523 655

Data Sheet

What size is your Activated Carbon Panel Filter?

If you don't know a section, leave it blank and we can help, or Click Here to get in contact.

Activated Carbon Panel Filter Applications

An Activated Carbon Panel Filter with its activated carbon filtration is ideal for removing unpleasant or even dangerous odours and gases from a wide variety of sources. Also with the ever increasing awareness of this problem from public health authorities and environmentalists has resulted in an increase in the use of the unique properties of activated carbon filtration.

Carbon will adsorb chemical molecules in the air stream in varying degrees according to the type of contaminant and the period of time the air remains resident in the carbon. Activated Carbon in it’s loose granular form can present problems as there is a tendency for granules to abrade one another, this causes both settlement of the carbon – creating potential bypass voids and produces carbon dust that can be re-entrained into the air-stream. Furthermore the unique bonding method eradicates these problems by producing a solid and stable biscuit of consistent quality and dimensional stability that produces an even resistance. Once formed the biscuits are bonded in a rigid mitred ‘U’ channel Frame or discarb matrix.

Due to the complex nature of adsorption carbon filters are generally designed to suit the application, however, the following information is given as an indication of the physical requirements for it’s use.

Activated Carbon Panel Filter Construction

Blocks of activated carbon bonded into a solid and stable biscuit style panel, surrounded by a metal channel header and sided by breathable flack material to contain and support the activated carbon panel filter.

Metal cased carbon discarbs hold multiple bonded activated carbon panels in a “block” which can then be easily installed into the duct. For more information check out our Activated Carbon Discarb Filter range

Operational Criteria for Activated Carbon

As far as possible water vapour should be eradicated from the air-stream to eliminate condensation within the filter that could cause porous blockage causing a dramatic increase in resistance – this also applies to loose carbon, however humidity levels as high as 80% RH are normally acceptable providing no interstitial condensation takes place.

Air-stream temperatures entering the filter in excess of 40°c should be avoided. In the case of anticipating temperatures above this level steps should be taken to reduce the temperature to an acceptable level by fresh air bleed, cooling coil or heat exchanger. In catering and food preparation applications smoke and grease must be removed from the air-stream prior to entry into the carbon

Dwell Times for Optimal Use

In order to ensure a carbon filter operates satisfactorily certain criteria need to be met which do not apply to particulate filters. The most important aspect is the “dwell time” (the period of time the air is in contact with the carbon). Also the minimum dwell time used is 0.1 seconds and this is shown below as maximum permissible airflow. Then the dwell time may increase considerably according to the contaminant to be removed.

Technical Information and Performance

Due to the complex nature of adsorption carbon filters are generally designed to suit the application, however, the following information is given as an indication of the physical requirements for it’s use.

| Filter Type | Typical Panel Size (HxWxD) |

Maximum Permissable Airflow (m3/s) at 0.1 sec dwell time |

Resistance at 0.1 sec (pa) | Resistance at 0.2 sec (pa) |

| Panel Frame | 595 x 595 x 20mm | 0.07 | 100 | 50 |

| Panel Frame | 595 x 595 x 45mm | 0.16 | 100 | 50 |

| Panel Frame | 600 x 600 x 22mm | 0.07 | 100 | 50 |

| Panel Frame | 495 x 495 x 18mm | 0.06 | 100 | 50 |