Our range of air filters

-

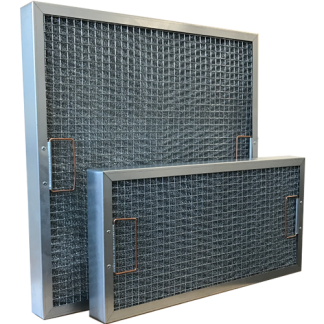

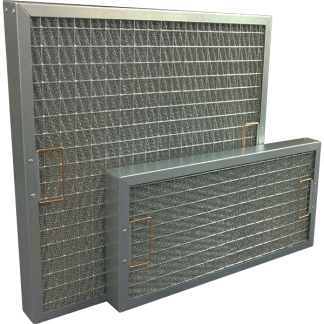

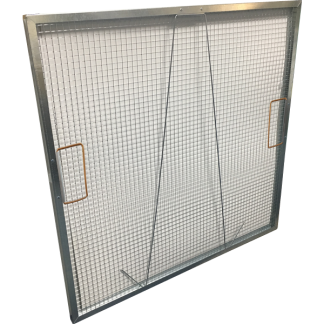

Kitchen Canopy Mesh Grease Filters

-

Extra Duty Kitchen Canopy Mesh Grease Filters

-

Kitchen Canopy Baffle Grease Filters

-

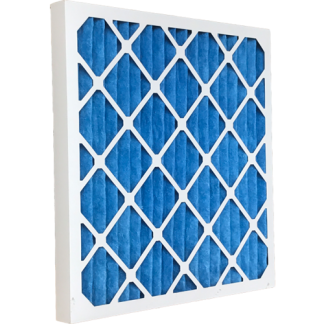

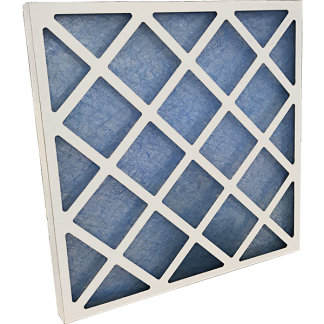

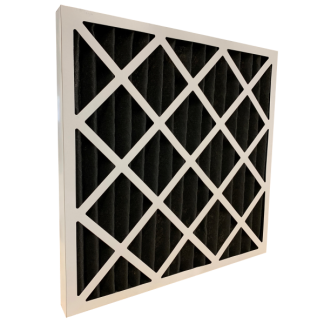

V Pleated Panel Air Filter G4 to EN779

-

Glass Fibre Panel Air Filter G2 – G3 to EN779

-

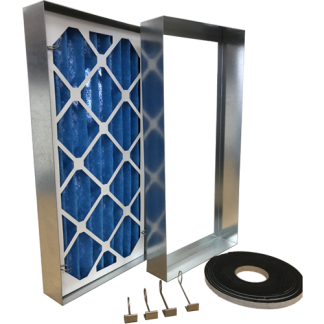

Pad Holding Frame for Filter Media

-

General Purpose Bag Air Filter G3 – G4 to EN779

-

High Efficiency Bag Filter M5, M6, F7, F8, F9

-

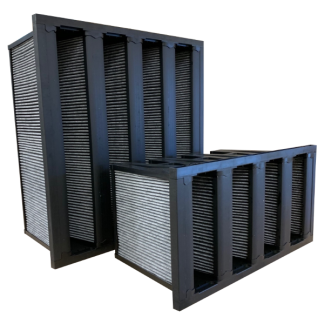

Rigid Bag Filter M6, F7, F8, F9 to EN779 E10 to EN1822

-

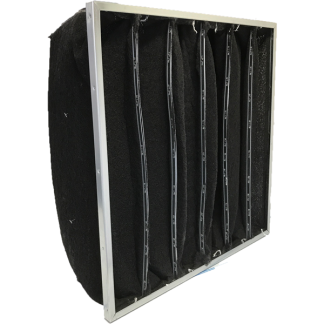

Activated Carbon Discarb Filter for Odour Removal

-

Activated Carbon Panel Filter for Kitchen Odour Removal

-

Activated Carbon Bag Filter

-

Activated Carbon Rigid Bag

-

Odour Pleat G4 Disposable Panel Filter

-

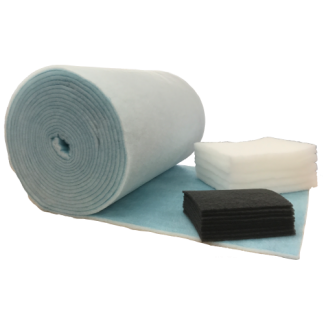

Glass Fibre Media Rolls and Cut Pads

-

Synthetic Filter Media Rolls and Cut Pads

-

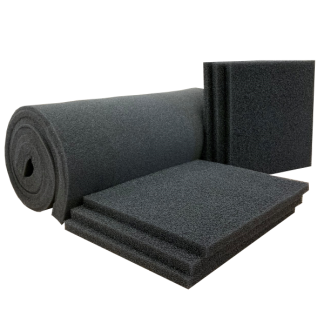

Poly Foam Media Rolls and Cut Pads

-

Binks Bullows Spray Booth Filter

-

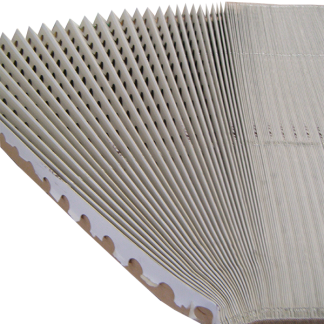

High Efficiency Pleated Panel Filters Grade M5, M6, F7 and F8

-

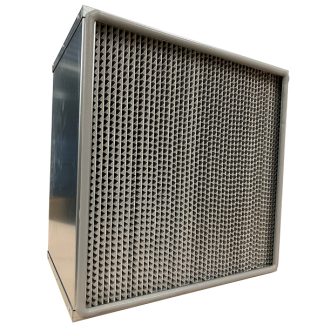

Mini Pleat HEPA Filter / Absolute Filter E10, H12, H14 to EN1822

-

Deep Pleat HEPA Filter Grade E10, E11, E12, H14 to EN1822

-

Front Withdrawal Frames and Side Withdrawal Housings

-

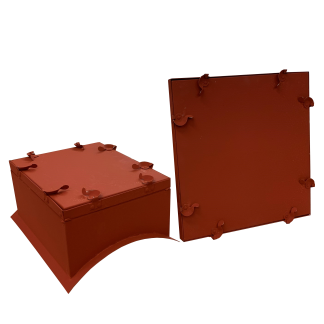

Access Doors and Panels for Ducts

-

Fire Resistant Access Doors

-

Drive Belts

-

Kitchen Extract Fans

-

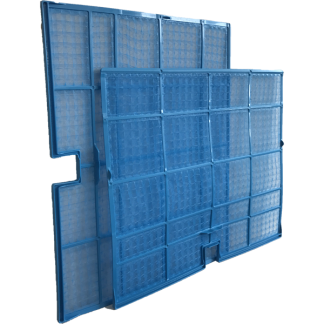

AC Split Unit Filters

-

Fire Extinguishers for Commercial Kitchens

£196.56 ex. VAT -

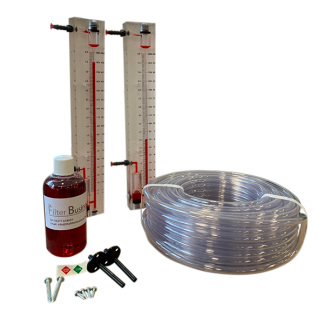

Filter Loss Gauge Fluid Incline Manometer

-

Ventilation Duct and Canopy Cleaning

Air filters – Manufacturer and Stockist from Essex

The Filter Business are an Air Filters stockist and manufacturer. We supply kitchen mesh grease and baffle filters for restaurant canopies. Panel and bag air filters for HVAC and air conditioning, and a range of bespoke filters for other industries. The Filter Business ships across the UK from our warehouse in Billericay, Essex.